THE SPRINGWOOD

THE SPRINGWOOD is functional, versatile, and unique to the industry. This design is actually the intersection of two Raleigh or two Raleigh II shelters. Most any size combinations can be selected, and either the traditional gable roof or the Dutch-hip roof is available for this structure. Architects and customers have told us that it is more cost-effective to enclose this pre-engineered, pre-fabricated shelter design than to build a traditional building from the ground up. It is the perfect answer to enclosed space under roof.

Popular available options include: metal roof, steel columns, surface mounted columns, staining, cupolas.

Photo GallerySHELTER SIZE

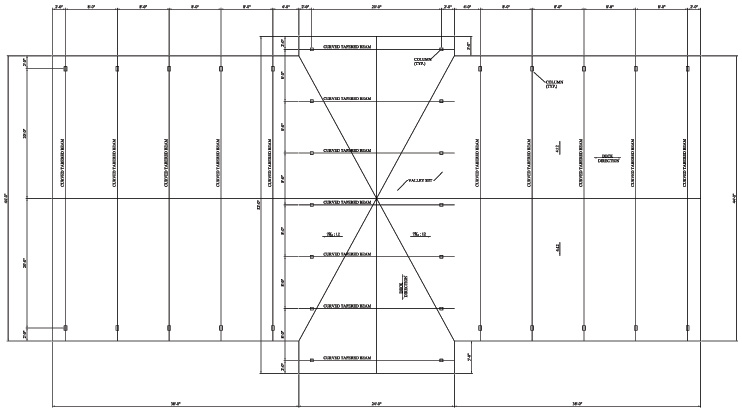

The size of the Springwood shelter is expressed by the width and the length of the roof area for each Raleigh or Raleigh II model selected. If Raleighs are selected, the column spacing is 8’ on center, and the standard overhangs are 2’. If Raleigh II’s are selected, then the column spacing would be 10’ on center, and the standard overhangs would be 2’6”.

THE SPRINGWOOD PACKAGE COMPONENTS

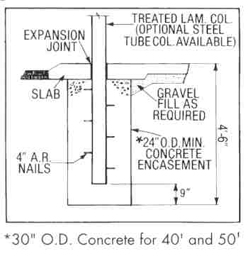

Columns:

Pressure treated, prior to gluing, laminated wood columns, 11’ 9” long – to be embedded 3’ 9” in the concrete for stability. The lumber is treated prior to gluing which affords full penetration to the core of the columns. Special 4” annular nails to be “partially nailed” into the portion of the columns embedded in the concrete footings to provide improved anchorage against wind uplift.

Curved-Tapered Beams:

Curved-tapered laminated wood beams that rest on the columns. Steel plates and bolts that connect the beams to the columns.

Roof Deck:

2x6 or 2x8” (nominal sizes) #1 grade Southern Yellow Pine wood decking, tongue and groove and end-matched, is nailed to the top of the beams. Galvanized nails to attach the deck to the beams.

Fascia:

2x6” pressure treated, #1 grade Southern Yellow Pine, fascia board to be attached at the eaves and gables. Galvanized nails to attach the fascia to the beam ends and the deck.

FELT & SHINGLES:

One layer of #30 roofing felt to be applied on top of the wood deck. 25 yr. 3-Tab fiberglass shingles, standard color Autumn Brown, other color options available upon request. Metal roofs available and priced upon request.

Enclosure materials are not supplied by EnWood.

ROOF PITCH

The standard roof pitch for the Raleigh and the Raleigh II is a 3:12 pitch. A roof pitch up to 5:12 can be provided.

DESIGN LOADS

- 12 pounds per square foot dead load

- 30 pounds per square foot live load

- 20 pounds per square foot wind load. (Equates to 100 MPH)

The typical design load allows for:

There are variables that affect the design sizes of the members, specifically the columns and the curved beams, and those variables generally include live load conditions that are usually location specific. Building Codes normally dictate the applicable loads to be applied in the member size designs.

PRESSURE PRESERVATIVE TREATMENT

As noted in the component list above, the laminated wood columns are fabricated with lumber pressure treated prior to gluing with CCA, at .6 pcf retention for ground contact. The fascia boards are treated with MCA or CCA, all treatment per AITC 109.

The treated Glulam can be stained or painted.

FOR DETAILED SPECIFICATIONS, PLEASE CLICK ON THE SPECIFICATION LINK

Custom Sizes & Designs Available

Roof Framing - 44' x 100' Springwood