THE BRANDYWINE

THE BRANDYWINE amphitheater with its extended coverage gives this pavilion its mult- functional usage. It is ideal for stage performances as well as a sheltered pavilion for seated events and gatherings. The design, with its pressure treated laminated wood open-knee arches services events both large and small. As with all of EnWood’s amphitheaters, the Brandywine pavilion is manufactured with #1 grade Southern Yellow Pine lumber. To assure long-term service and low maintenance, all wood components are fabricated with pressure treated lumber, and all steel base shoes, connectors, and hardware are galvanized

Specification Sheet (PDF) | Photo GallerySHELTER SIZE

The standard sizes of the Brandywine are still in the development stage. Please call the sales office at EnWood Structures, 800.777.8648, to discuss your size requirements. Custom sizes are also available.

THE BRANDYWINE PACKAGE COMPONENTS

OPEN-KNEE ARCHES:

Pressure treated, prior to gluing, laminated wood arches that attach to the top of the concrete foundation. Lumber is treated prior to gluing which affords full penetration of the core of the arches. Galvanized steel base shoes and bolts attach the base of the arch to the concrete.

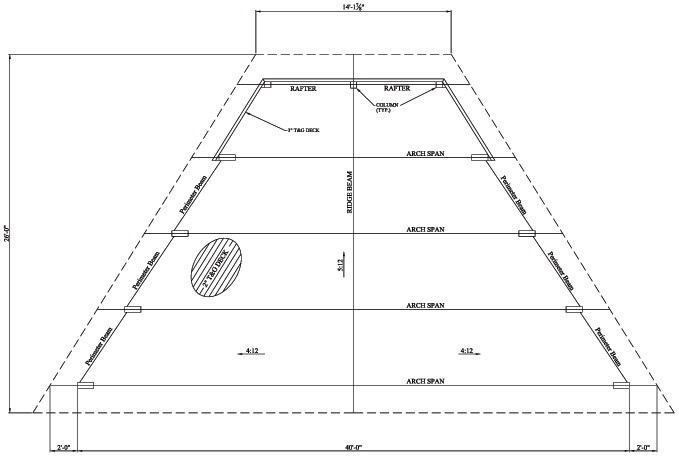

RIDGE BEAM:

Laminated wood ridge beam, #1 grade Southern Yellow Pine, sized as pre design requirements.

WALL DECK:

Pressure treated, two inch (2”) or three inch ( 3”) (nominal sizes) #1 grade, Southern Yellow Pine, tongue and groove, wood decking. Galvanized nails

ROOF DECK:

2x6 or 2x8 (nominal sizes) #1 grade, Southern Yellow Pine wood decking, tongue and groove is nailed to the top of the arches. Galvanized nails to attach the deck to the beams.

FASCIA BOARDS:

Pressure treated, 2x6, #1 grade Southern Yellow Pine, fascia board to be attached at the eaves. Galvanized nails to attach the fascia to the beam ends and the deck.

FELT & SHINGLES:

One layer of #30 roofing felt to be applied on top of the wood deck. 25 yr. 3-Tab fiberglass shingles, standard color Autumn Brown, other color options available upon request. Metal roof available and priced upon request.

ROOF PITCH

The front to back pitch of the roofline, and the side roofline pitch is 4:12.

DESIGN LOADS

- 12 pounds per square foot dead load

- 30 pounds per square foot live load

- 20 pounds per square foot wind load. (Equates to 100 MPH)

The typical design load allows for:

There are variables that affect the design sizes of the members, specifically the columns and the curved beams, and those variables generally include live load conditions that are usually location specific. Building Codes normally dictate the applicable loads to be applied in the member size designs.

PRESSURE PRESERVATIVE TREATMENT

As noted in the component list above, the wood columns are fabricated with lumber pressure treated (prior to gluing) with CCA, at .6 pcf (6 tenths of a pound of preservative per cubic foot of wood) retention for “ground contact”. Fascia boards are treated with MCA or CCA,all the treatment per AITC 109. The treated glulam can be stained and painted.

FOR DETAILED SPECIFICATIONS, PLEASE CLICK ON THE SPECIFICATION LINK

Standard Shelter Sizes Available

Custom Sizes & Designs Available

| 35' x 25' | 55' x 25' |

| 39' x 25' | 51' x 32' |

| 43' x 25' | 55' x 32' |

| 47' x 25' | |

| 51' x 25' |

Roof Framing - 30' x 60' Raleigh